MYUAV DRONE Wind Turbine Blade Automatic Inspection Plan: Wind Power Guardian

Wind power generation is an important renewable energy source, and wind turbine blades are one of the most critical components in wind power generation equipment. However, due to the long-term exposure of wind turbine blades to the natural environment, their inspection and maintenance have always been a challenge for the wind power generation industry. The traditional inspection method requires a lot of manpower and time costs, and due to certain safety hazards during the inspection process, the inspection efficiency is low. The emergence of MYUAV DRONE wind turbine blade automatic inspection technology has brought new changes to the wind power generation industry.

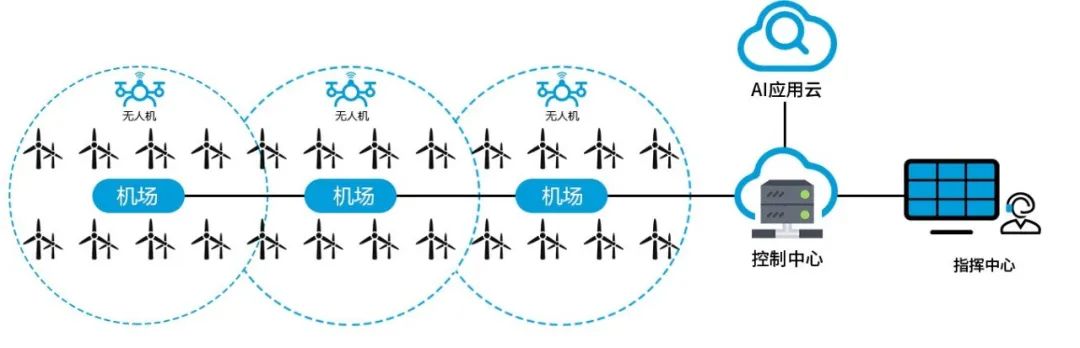

Automatic Inspection System for Fan Blades

1. MYUAV DRONE

Equipped with a variable focus camera and LiDAR, for autonomous path planning and image shooting of wind turbines.

2. Automatic airport

The MYUAV DRONE automatic airport provides all-weather protection for MYUAV DRONE, achieving takeoff, landing, storage, and battery management through automated opening and closing and lifting structure design. Automatic takeoff and landing, autonomous patrol, automatic charging and other functions replace manual on-site operation of the MYUAV DRONE.

3. Command Center

The command backend is mainly responsible for the mission of the MYUAV DRONE control center and is the core part of the entire MYUAV DRONE command system. By interacting with the data transmitted by MYUAV DRONE, real-time monitoring of the inspection status of MYUAV DRONE wind turbine blades is achieved, and AI recognition, analysis, processing, and storage of collected images, videos, sensor data, etc. are carried out to provide data support for subsequent applications.

Identify defect categories through inspection

1. Wear: There may be wear on the surface of the fan blades, such as scratches, abrasions, smoothing, bulges/wrinkles/surface depressions.

2. Stains: Surface oil stains/stains.

3. Corrosion: Due to the influence of climate and environment, fan blades may exhibit corrosion phenomena, such as corrosion spots, corrosion holes, etc.

4. Cracks: Due to long-term stress, fan blades may experience cracks, such as small surface cracks, more severe cracks, and even cracks.

5. Adhesive layer peeling: The adhesive layer on the fan blades may experience peeling phenomena, such as coating peeling, glass fiber layer peeling, etc.

6. Bending or deformation: Due to external forces or abnormal conditions, the fan blades may bend or deform, affecting their normal operation.

7. Equipment damage: After prolonged operation, there may be areas where the fan blades may break or be damaged, as well as missing accessories, damaged lightning arresters, and detached rain rings.

8. Debris accumulation: The surface of the fan blades may accumulate debris, such as sand, bird droppings, etc., which can affect the performance of the fan.

Simulation of Automatic Airport Layout and Planning for Wind Farm

1. Preparation work

The fan is shut down, and under dynamic conditions, due to changes in the position of the fan blades in the field of view, it is difficult to focus, resulting in poor imaging effect and affecting the accuracy of video classification processing; Check if all equipment of MYUAV DRONE is functioning properly, including aircraft, cameras, mission sensors, etc. At the same time, ensure that the battery is fully charged so that it will not be interrupted during the inspection process due to insufficient battery power.

2. Planning route

Based on the position, size, and layout of the wind turbines, as well as the flight performance of the MYUAV DRONE, plan the inspection route in advance. The route should cover all fan blades to ensure a comprehensive inspection.

3. Takeoff and Navigation

Following the planned route, control the MYUAV DRONE to take off and fly along the set path. During the flight, monitor the status of the MYUAV DRONE in real-time to ensure stable flight.

4. Image acquisition

During the flight, MYUAV DRONE takes photos of the fan blades at the set frequency. The photos taken should clearly display the surface condition of the blades for subsequent analysis.

5. Data transmission

MYUAV DRONE sends real-time flight parameters and captured photos to the ground workstation. The ground workstation receives data and performs preliminary real-time analysis.

6. Defect/Fault Analysis

The command center conducts a detailed analysis of the received photos to identify defects/faults on the surface of the blades. If obvious defects/faults are found and the photos meet the subsequent analysis requirements, the location of the defects/faults shall be marked, but the normal inspection of MYUAV DRONE shall not be interrupted.

7. Suspected defect handling: If the analysis results show suspected defects in the blades, the command center will send an alarm command to MYUAV DRONE. MYUAV DRONE hovers on site according to instructions, processes according to pre-set procedures, or intervenes manually.

8. Data storage and analysis: Store the data and analysis results collected during the inspection process in a database for future querying and analysis. By continuously accumulating data, the MYUAV DRONE inspection strategy can be optimized to improve inspection efficiency.

9. Record and report of inspection results: After MYUAV DRONE completes the inspection, the command center summarizes and analyzes the results, and generates a report. The report includes the parts of the blades that are in good condition, as well as the parts with defects, for subsequent repair and maintenance.

--DRONE SOLUTION PROVIDER--

MYUAV® TECHNOLOGIES CO.,LTD.

Tax No.: 91320118MA275YW43M Legal Register No.: 320125000443821

Add:No.89,Pingliang Street,Jianye District, Nanjing,China 210019

M: myuav@myuav.com.cn T:+86 25 6952 1609 W:en.myuav.com.cn

[Caution]MYUAV™ is a manufacturer of defense products and is under security management by a state agency.

Drawings, materials, samples, etc. provided by us shall be used only for the purposes provided.