Overview of leakage detection scheme for underground gas pipelines using MYUAV DRONE methane detector

The Importance of Gas Underground Pipeline Inspection

Gas is a flammable and explosive gas, and its safe use and management are crucial. The underground pipeline is the carrier of gas transportation, and its safety is directly related to the safety and stability of gas supply. Through regular inspections, safety hazards such as leaks, damages, and blockages can be detected and dealt with in a timely manner, preventing accidents such as gas leaks and explosions. In addition, the aging of urban underground comprehensive pipelines may lead to corrosion, aging, and other safety hazards such as pipeline leakage and rupture. To ensure the safe operation of underground pipelines, regular inspections are also necessary to identify these hidden dangers and take corresponding measures for repair and maintenance. Therefore, it is particularly necessary to carry out regular inspections of gas bottom line pipelines.

Limitations of early underground gas pipeline inspection

Early detection methods used in the automatic flight inspection of the MYUAV DRONE route showed that the projection of point laser along the flight direction of the MYUAV DRONE on the ground was a line, and the width, which is the diameter of the laser spot, usually did not exceed 20cm. However, the diameter of high-pressure natural gas pipelines mostly exceeded 50cm. In addition, the flight error of the MYUAV DRONE required multiple back and forth flights of the MYUAV DRONE to cover the pipelines that needed inspection, which was very inconvenient.

Product advantages

In order to compensate for the limitations of laser methane detectors, a laser ground scanning gimbal was developed. The MYUAV DRONE flies above the pipeline, with a three-axis stabilized gimbal maintaining the direction of laser irradiation perpendicular to the ground. The scanning controller controls the rotation of the gimbal, and the projection of the laser irradiation on the ground takes on a spiral shape, sweeping over a certain width (about 3-10m). As a result, the MYUAV DRONE can cover the pipeline range that needs to be inspected in one flight, compensate for flight position errors, and capture leaking air masses that deviate from the pipeline, improving the success rate of real-time detection and inspection efficiency.

LC30pro [5G version]

The LC30 pro [5G version] product has made targeted optimization designs in terms of volume, weight, power consumption, and electromagnetic interference, targeting the application characteristics of the MYUAV DRONE. The response time of 25 milliseconds ensures that the MYUAV DRONE can maintain stable and reliable data output even during high-speed movement. It has the characteristics of high sensitivity, high measurement accuracy, low detection limit, and fast response speed, and almost does not require maintenance and on-site measurement calibration.

Compared to traditional electrochemical sensor detection methods, LC30pro [5G version] can achieve non-contact measurement, quickly detect trace amounts of methane gas in the air, with a maximum detection distance of 150 meters and is not affected by environmental factors such as temperature, humidity, and pressure, and has very high stability.

APP control: Open the Android desktop icon and enter the login interface of the Laser Methane APP. During the inspection process, the MYUAV DRONE status and methane measurement data can be viewed in real time. In case of pipeline leakage, the terminal equipment will automatically alarm and record data (time, coordinates, leakage concentration, on-site photos) for automatic generation of inspection reports in the later stage.

Web control: Unified monitoring and management of methane data. Capable of calling maps, switching between 3D/2D/planar views, displaying 3D flight trajectories, displaying color block values, displaying real-time data, marking points and measurements, statistics of abnormal areas, quick positioning, querying historical records, and exporting reports.

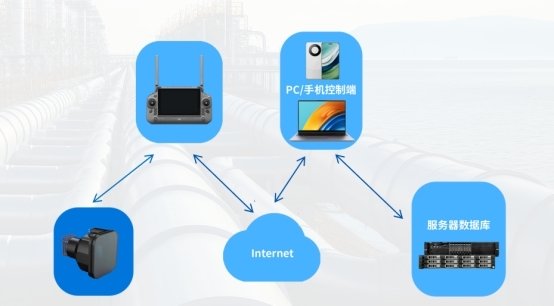

system composition

The L30Pro [5G version] laser methane detector can currently be mounted on DJI M300RTK and M350RTKMYUAV DRONE for use. It can transmit the methane concentration data collected by the sensor to a remote control APP or webpage for display through various transmission methods such as 5G module and DJI SDK.

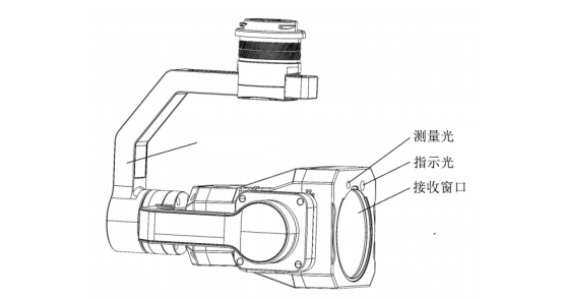

Structural composition

The laser emission and reception modules are integrated inside the probe, and the receiving unit inside the probe includes a signal receiving circuit, an amplification circuit, and a processing circuit. The central processing unit adopts dual processors. One is a DSP processor used for floating-point operations, which can accurately and quickly test gas concentration, while the other processor is used for functional control, status detection, communication, and other functions of the entire system. The measurement laser is emitted by the collimator after secondary focusing, ensuring that the diameter of the spot is less than 20cm beyond 150m, and ensuring that the emitted light signal is strong enough to reduce interference from sunlight docking and improve signal-to-noise ratio. The external part of the probe consists of a three-axis gimbal, a measuring laser hole, an indicating laser hole, and a receiving window.

Product Plan Composition

The MYUAV DRONE laser methane underground pipeline inspection system is a comprehensive system that includes MYUAV DRONE, LC30pro [5G] sensors, and ground control centers, working together to achieve efficient gas underground pipeline leakage inspection.

MYUAV DRONE: This is the core of the entire system, responsible for executing LiDAR scanning and methane concentration detection tasks. It needs to have sufficient stability, anti-interference ability, and endurance to adapt to the environment of underground pipelines.

LC30pro [5G] sensor: The MYUAV DRONE needs to be equipped with various sensors, such as methane sensors, which can monitor the methane concentration in underground pipelines in real time. If the methane concentration exceeds the safe range, the sensor will sound an alarm.

Ground Control Center: This is another key part of the entire system (including PC control end and APP control end), responsible for receiving data transmitted by MYUAV DRONE, conducting data analysis and processing, and providing a basis for pipeline maintenance and repair.

--DRONE SOLUTION PROVIDER--

MYUAV® TECHNOLOGIES CO.,LTD.

Tax No.: 91320118MA275YW43M Legal Register No.: 320125000443821

Add:No.89,Pingliang Street,Jianye District, Nanjing,China 210019

M: myuav@myuav.com.cn T:+86 25 6952 1609 W:en.myuav.com.cn

[Caution]MYUAV™ is a manufacturer of defense products and is under security management by a state agency.

Drawings, materials, samples, etc. provided by us shall be used only for the purposes provided.