Fault identification and positioning of MYUAV DRONE photovoltaic power station, deployment plan for ground air integrated inspection software

- Overview of MYUAV DRONE Photovoltaic Power Station Inspection Software

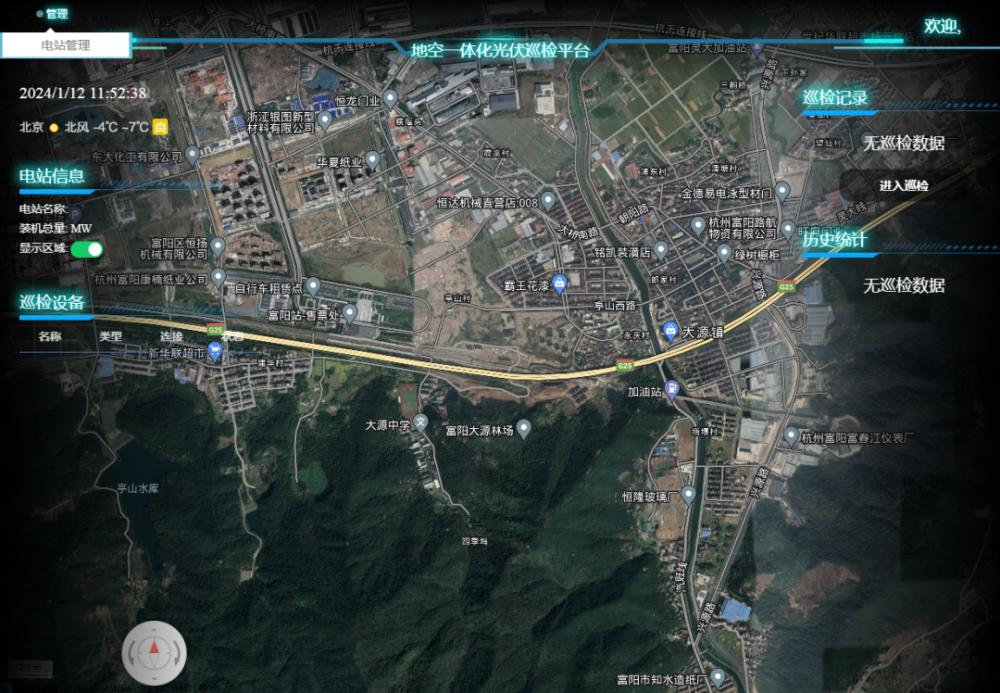

The software is based on the B/S architecture, utilizing the "cloud platform+algorithm application container" framework and artificial intelligence technology to achieve an integrated management and control platform for the MYUAV DRONE photovoltaic power plant, improving the inspection efficiency of the power plant.

Based on the advanced dual light fusion recognition model, synchronous interpretation of dual light information, comprehensive judgment, accurate identification of string quantity and defects, precise positioning, precise grading, can achieve automatic classification of danger levels for faults, and provide reliable fault diagnosis and positioning services. In addition, it can also generate detailed inspection reports to help power station management personnel discover and solve problems in a timely manner.

The integration of ground and air inspections has been achieved, and the data from air and ground inspections can be transmitted, shared, and analyzed in real time, providing more comprehensive and accurate information for the operation and maintenance of power plants.

Software deployment considerations

When deploying software, a thorough environmental investigation and on-site investigation of the photovoltaic power plant should be conducted first. Based on the scale, layout, and equipment condition of the power station, determine the optimal MYUAV DRONE inspection route and ensure a good communication signal environment near the photovoltaic power station. Secondly, it is important to focus on the security and stability of the software, ensuring that it can operate normally in various harsh working environments and protecting the privacy and security of inspection data.

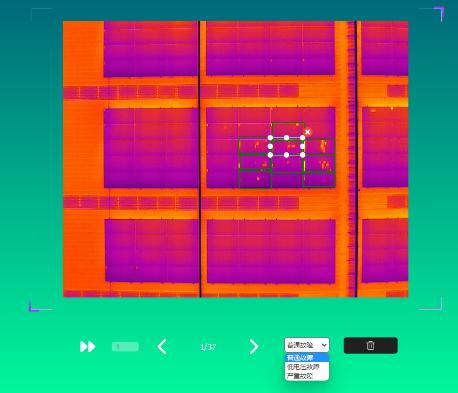

l Fault identification function

A defect intelligent algorithm based on infrared thermal imaging images, the system automatically identifies defects in the images and can classify them by type. The intelligent recognition results can be manually reviewed by clicking on the defect recognition box to identify and fill in any gaps.

Fault location function

Perform coordinate projection transformation based on the fault location information of the called image, convert the pixel coordinates of the image into spatial longitude and latitude information, calculate the position of the fault in spatial coordinates, display the fault location in the corresponding orthophoto file, and mark it on the map. The service is equipped with an internal route coordinate conversion system from WGS84 to GCJ02, and combined with defect pixel information in the image and flight altitude of the route, it accurately locates defects. At the same time, in conjunction with high-precision map services, it uses string matching to perform string level fault localization, and achieves linkage between defects and photovoltaic strings. And it supports manual adjustment of defect positions.

Integrated Platform for Ground Air Integrated Photovoltaic Power Station Inspection System

1. User unified authentication: All platforms of the system use unified user authentication, using dynamic token encryption authorization mechanism for authentication, while allowing hierarchical management, clear division of permission information, and ensuring system security;

2. Ground equipment monitoring: To achieve real-time monitoring and control of various equipment in photovoltaic power plants, including battery packs, inverters, distribution boxes, transformers, etc. Integrate the MYUAV DRONE inspection system and ground equipment control system to form a complete ground air integrated intelligent control system for photovoltaic power plants, achieving real-time monitoring, data analysis, and equipment control in all aspects, and improving the operational efficiency and safety of photovoltaic power plants.

3. Airport monitoring: including real-time detection of airport video streams, meteorological conditions, and power supply conditions.

4. MYUAV DRONE monitoring: Real time display of MYUAV DRONE's status, health status, and live stream monitoring.

5. Command screen: The command screen integrates status information, video streams, maintenance personnel status, inspection status, and other information of all equipment, including ground and air equipment.

--DRONE SOLUTION PROVIDER--

MYUAV® TECHNOLOGIES CO.,LTD.

Tax No.: 91320118MA275YW43M Legal Register No.: 320125000443821

Add:No.89,Pingliang Street,Jianye District, Nanjing,China 210019

M: myuav@myuav.com.cn T:+86 25 6952 1609 W:en.myuav.com.cn

[Caution]MYUAV™ is a manufacturer of defense products and is under security management by a state agency.

Drawings, materials, samples, etc. provided by us shall be used only for the purposes provided.