Road maintenance: MYUAV road surface disease (crack) identification system

Road maintenance: MYUAV road surface disease (crack) identification system

MYUAV road surface disease (crack) identification

Drones are widely used in industrial fields. With the continuous development and progress of their technology and the intelligent upgrading of applications in various industry fields, the practical application value of drones is also constantly increasing. In the field of transportation, highway maintenance and management work directly affects people's daily travel and the development of the national economy, so periodic and regular maintenance is particularly important.

In order to ensure the long-term use of highways and traffic safety, and to keep highways and ancillary facilities in good technical condition, R&D personnel use drones combined with road surface disease detection technology to take advantage of the flexibility and high degree of intelligence of drones in highway maintenance and inspection. Pioneering and innovating in the field.

Advantages of pavement disease (crack) inspection

Traditional inspections have problems such as inefficiency and cumbersomeness, subjective and extensive inspections, excessive inspection time, personnel safety, and inability to accumulate daily maintenance data. Use drones to improve inspection efficiency, reduce the frequency of overhauls and extend road life through preventive maintenance.

Overview of pavement disease (crack) inspection system

The drone terminal collects on-site road photos or videos, transmits them to the back-end server in real time, imports the algorithm recognition system, automatically performs AI recognition, and displays the data results visually.

Principle of crack identification algorithm

The road damage algorithm identification and inspection system trains road crack disease images based on deep learning algorithms to realize identification, segmentation and statistics of road cracks. The algorithm is efficient, accurate and stable. It can continuously identify the road photo data transmitted in real time. It can automatically identify cracks of more than 5mm on the road and ensure a recognition rate of more than 85%.

Deep learning adopts the transfer training mode for training, which can achieve a high degree of adaptability to different scenarios and can perform targeted upgrades according to the needs of specific problems. It retains the sustainable update capability of the algorithm and can achieve faster detection speed, higher detection accuracy, and more types of disease detection through background updates. It can realize the continuous progress of a set of algorithms within the hardware cycle.

Overview of inspection steps for pavement diseases (cracks)

1. Route planning

Based on the inspection requirements and surrounding airspace environment, combined with the aircraft's endurance, the route can be initially planned and appropriate take-off and landing points can be selected to estimate the number of aircraft batteries required, design flight routes and battery replacement opportunities, and improve operational efficiency.

2. Determine the inspection area

Determine the crack inspection area and conduct an overall survey of the surrounding environment. Pay attention to surrounding trees, high-rise buildings and high-voltage line towers to prepare for signal testing, collection and selection of take-off and landing points.

3. Demarcate take-off and landing points

Choose a venue with no obvious signal obstruction. In order to ensure the signal quality of the aircraft's RTK function, it is necessary to ensure that the take-off point is open and free of obvious signal obstructions.

4. Pre-flight inspection

Before taking off, the drone must be inspected as a whole and the key inspection parts must be confirmed one by one. After confirmation, the flight inspection is completed.

5. Route flight

The collection route should strictly follow the inspection requirements. After the aircraft stops, collect waypoint information (pointing). The starting point and end point of the route should be the highest point of the route. When collecting, keep the aircraft within the visual range and avoid obstacles.

6. Data processing

After the route collection is completed, export the kml route to our company or import it into the cloud platform yourself. Perform data processing.

7. Perform AI crack recognition processing on collected materials

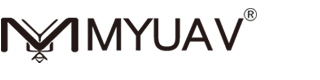

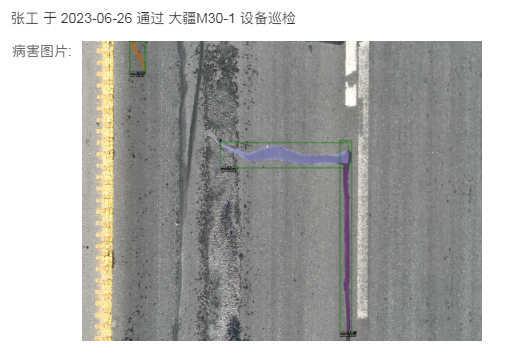

Upload the pictures collected during the inspection to the background of the crack identification software to identify and process the pictures.

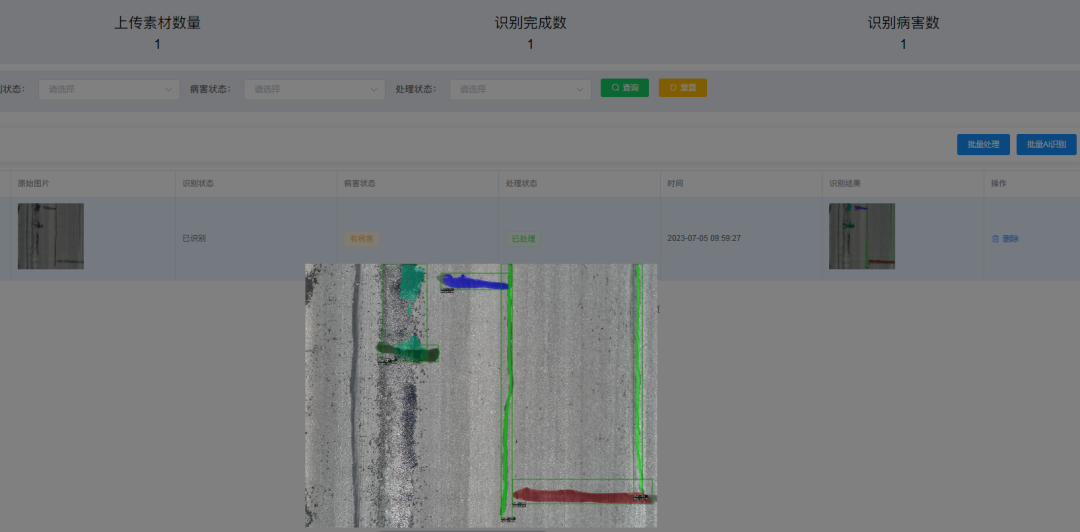

8. Generate and export crack data report

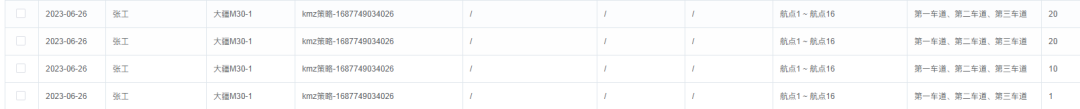

Inspection reports are automatically generated based on the uploaded materials and material identification results. Inspection records are queried according to search conditions and then the inspection records are checked for merge and export.

Crack identification processing function

Automatically identify road diseases in specified pictures and videos, and import the picture path at the specified location. The program can automatically identify road cracks in the target pictures and videos, and display the visual map.

At the same time, data tables can be automatically generated for statistical results to facilitate subsequent statistical analysis.

--DRONE SOLUTION PROVIDER--

MYUAV® TECHNOLOGIES CO.,LTD.

Tax No.: 91320118MA275YW43M Legal Register No.: 320125000443821

Add:No.89,Pingliang Street,Jianye District, Nanjing,China 210019

M: myMYUAV@myMYUAV.com.cn T:+86 25 6952 1609 W:en.myMYUAV.com.cn

[Caution]MYUAV™ is a manufacturer of defense products and is under security management by a state agency.